- Products

- Applications

- …

- Products

- Applications

- Products

- Applications

- …

- Products

- Applications

Services

Professional engineering service is the core competitiveness of SIMTEK. Successful use the model-based design method to promote product development strongly depends on the engineering background, rather than the implementation tools. The members of SIMTEK team have many years of engineering service experience for world leading manufacturing enterprises, and have the professional solutions of handling product design cases based on model. Modeling and simulation gradually play a significant role in the process of project implementation. Besides, team engineers are well versed in modeling language design, compilation, system solution, and have rich professional background knowledge. SIMTEK provides comprehensive and flexible professional services, such as modeling and simulation for detailed performance of complex dynamic systems , design and optimization of control systems and system engineering consultation etc.

Model Development | System Simulation | Model-based Optimization | Software Development | Design and Development of Servo Motor | Training

Model Development

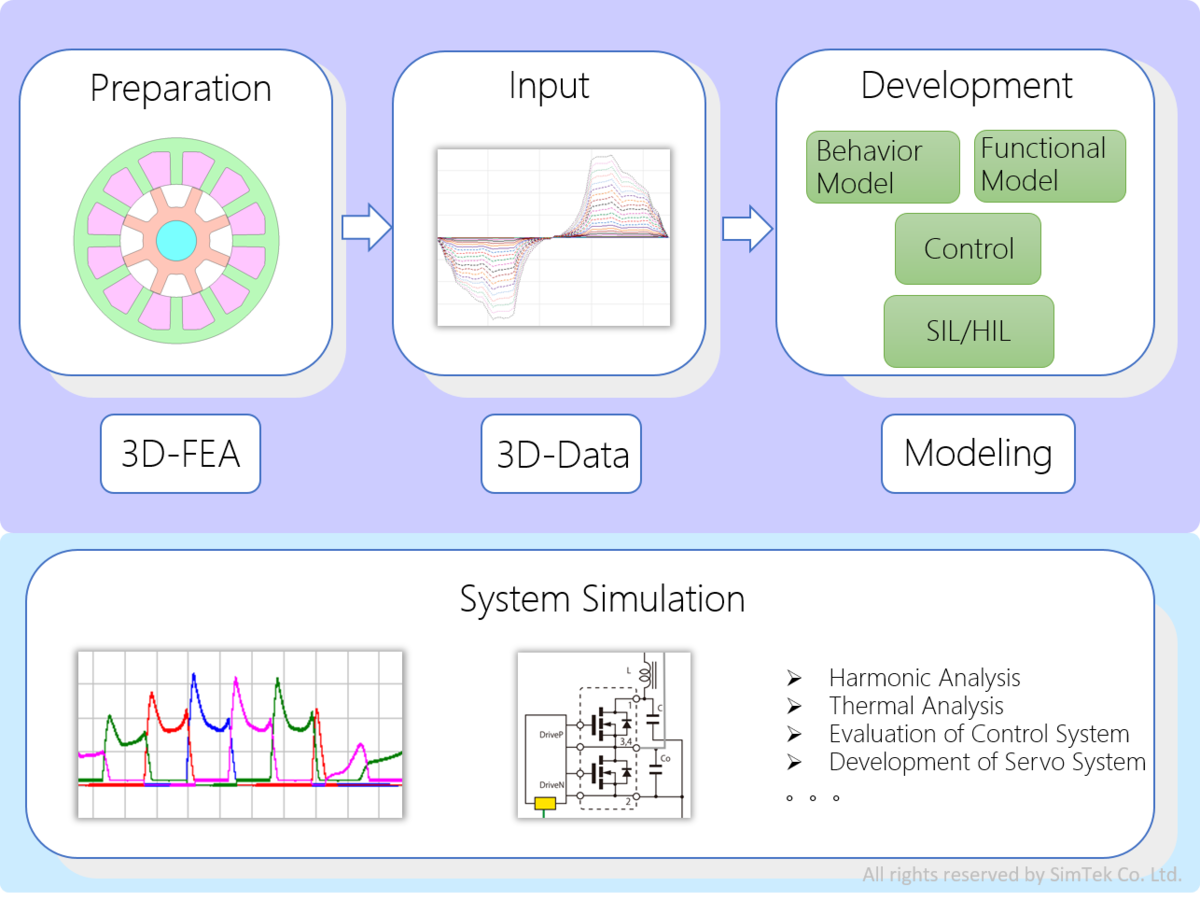

Accurate and efficient model is the key factor of model-based design. SIMTEK has deep knowledge on modeling technology for dynamic systems covering different physical disciplines such as electric, control, thermal fluid and others. Rich modeling experience in the fields of aircraft, railways, new energy vehicles, fuel cells and motor systems give customers more confidence when cooperating with us. SIMTEK provides customers modeling services complying with industry modeling standards, including

- Model specification

- Multi-level modeling

- Development of control model and plant model

- Validation and verification

- Development of real-time model

- Design and development of aircraft electrical system model

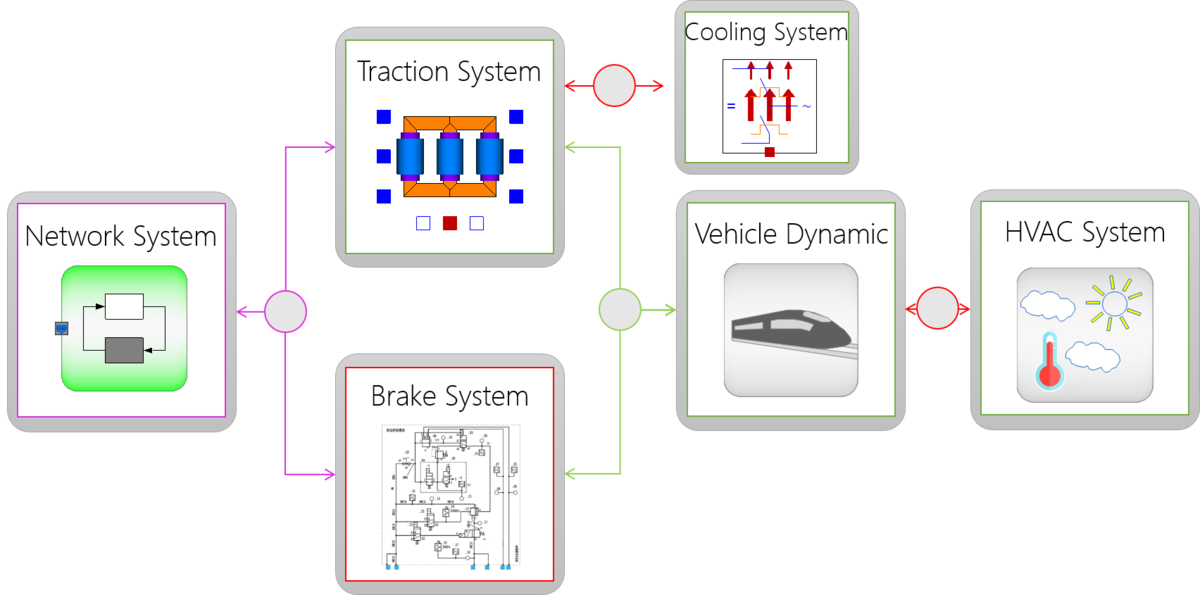

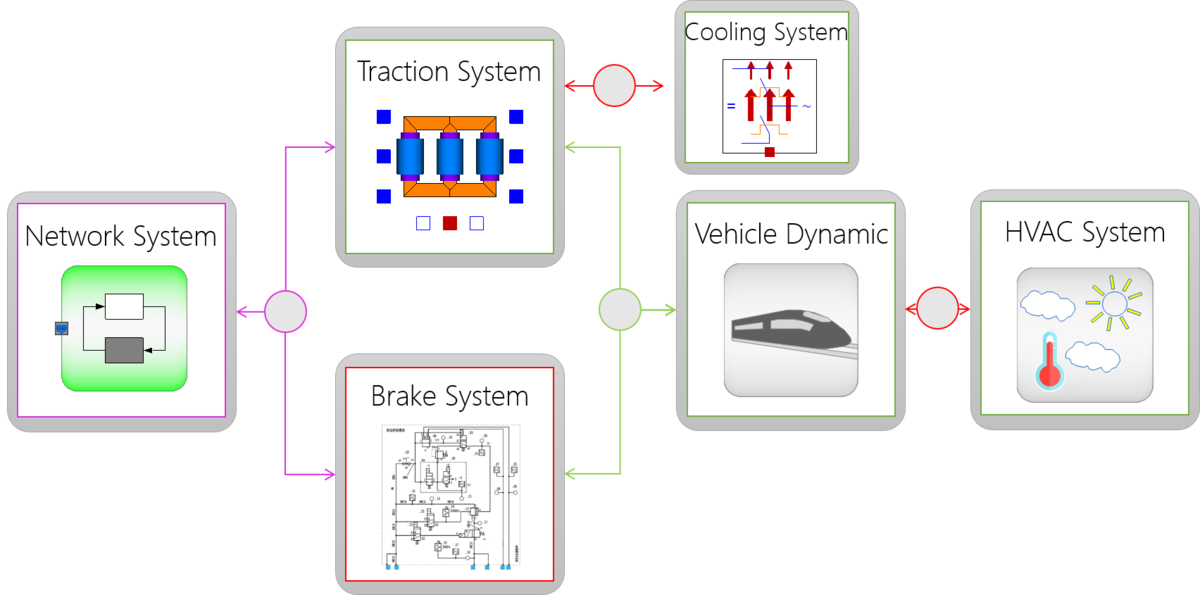

- Design and development of key subsystem model for high speed EMU

- Design and development of fuel cell system model

- Design and development of automotive powertrain model

- Design and development of motor system model

Simulation of complex dynamic systems

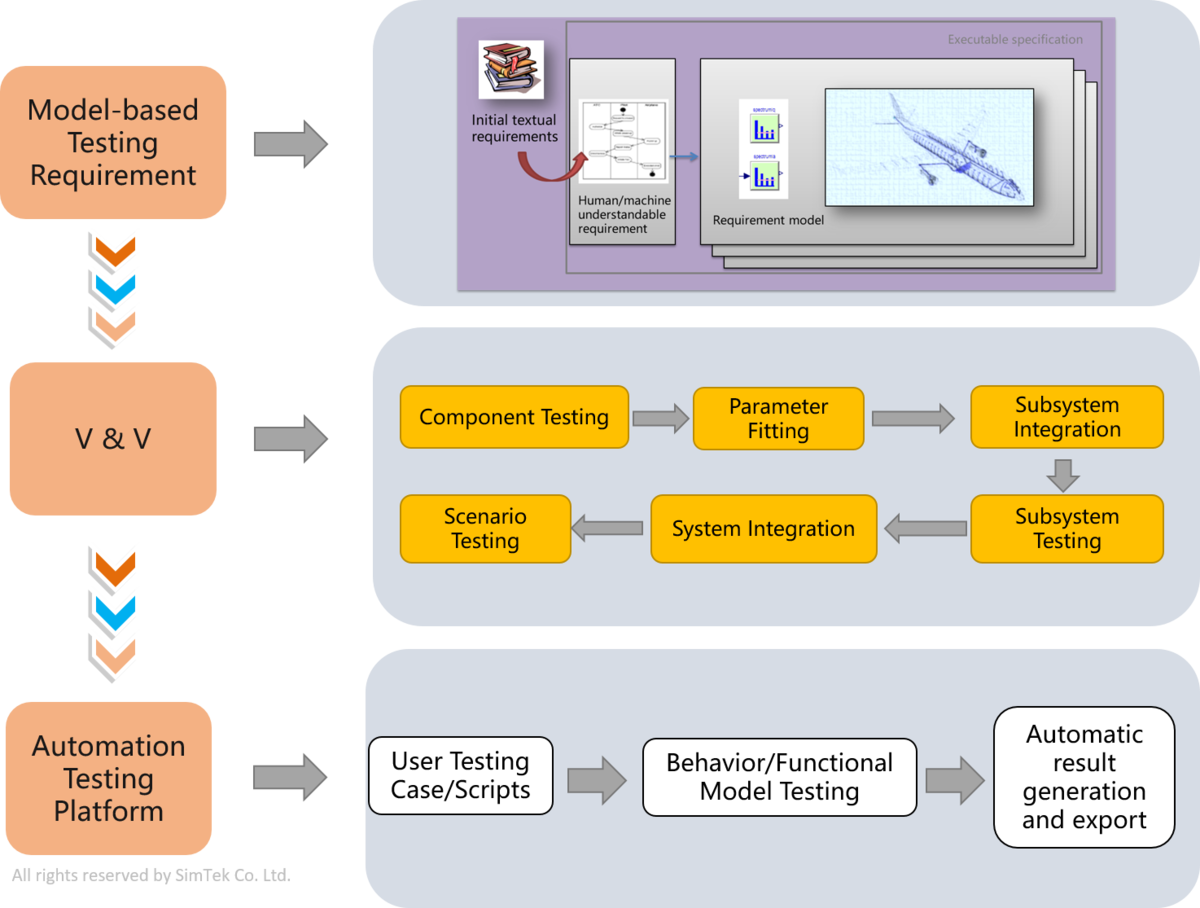

To promote virtual testing and optimization of related systems, after modeling and verification, it is necessary to implement system integration. Currently, there are so many challenges in system simulation field, such as low efficiency of integrated model, rebuilding heterogeneous models with different simulation tools, lack of standarized virtual testing process and so on. Based on the engineering experience coming from related European Commission industry projects in last years, SIMTEK has strong ability to model and simulate dynamic models of complex systems using Modelica language and FMI standard in a very standardized and efficient way. By modeling systems in proper detail level, SIMTEK replicates the essential process occurring in real systems, adapts to different needs of product development cycles, and deeply explores the actual physical characteristics and control logic of the system. SIMTEK provides professional and comprehensive system simulation services, such as

- System model integration

- Modeling requirements and acceptance criteria

- Assist customers to integrate & accept models

- Virtual testing and verification based on integrated model

- SIL & MIL & HIL

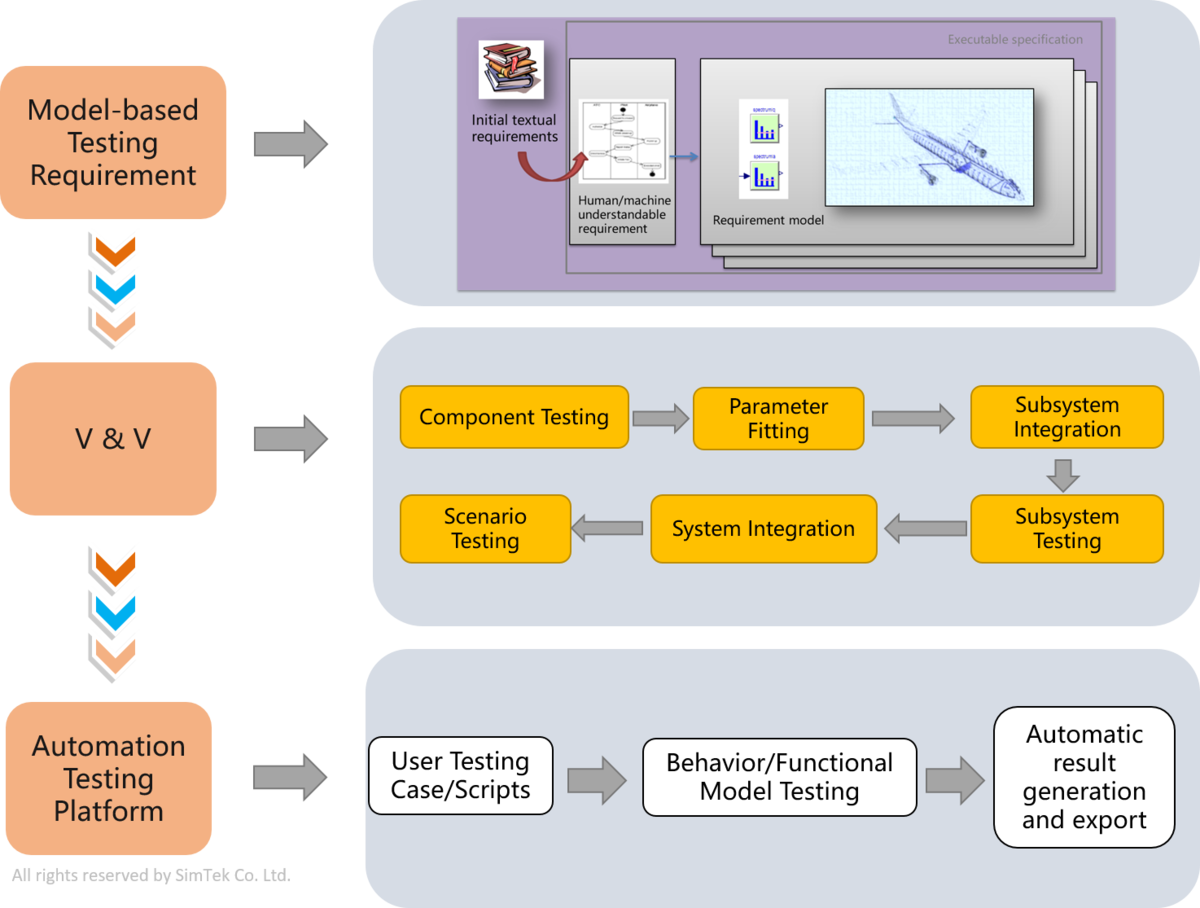

- Design and development of virtual model automatic test platform

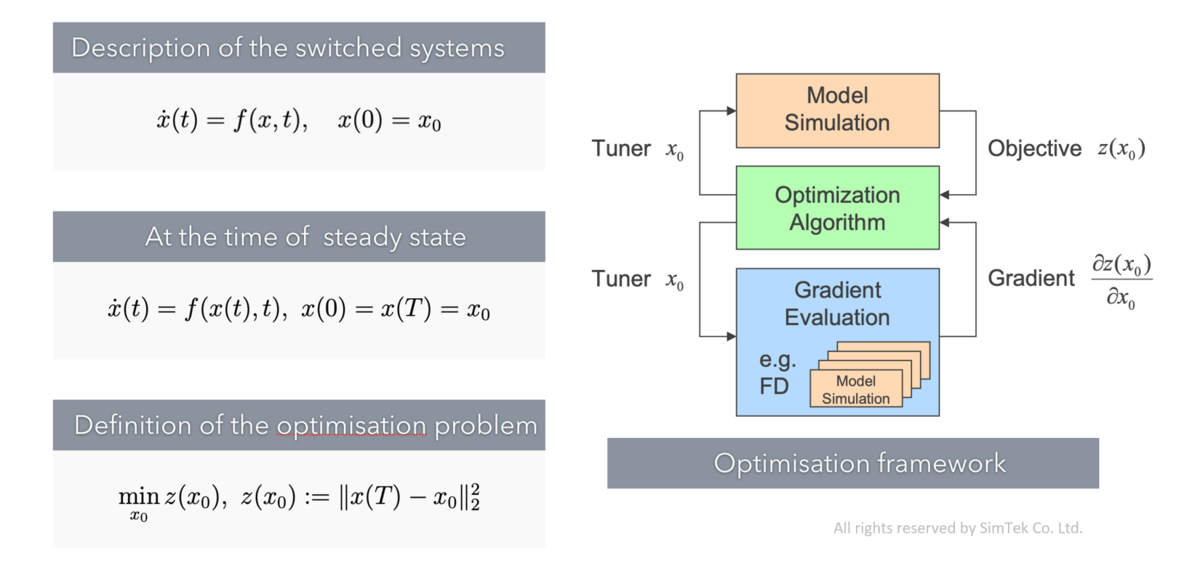

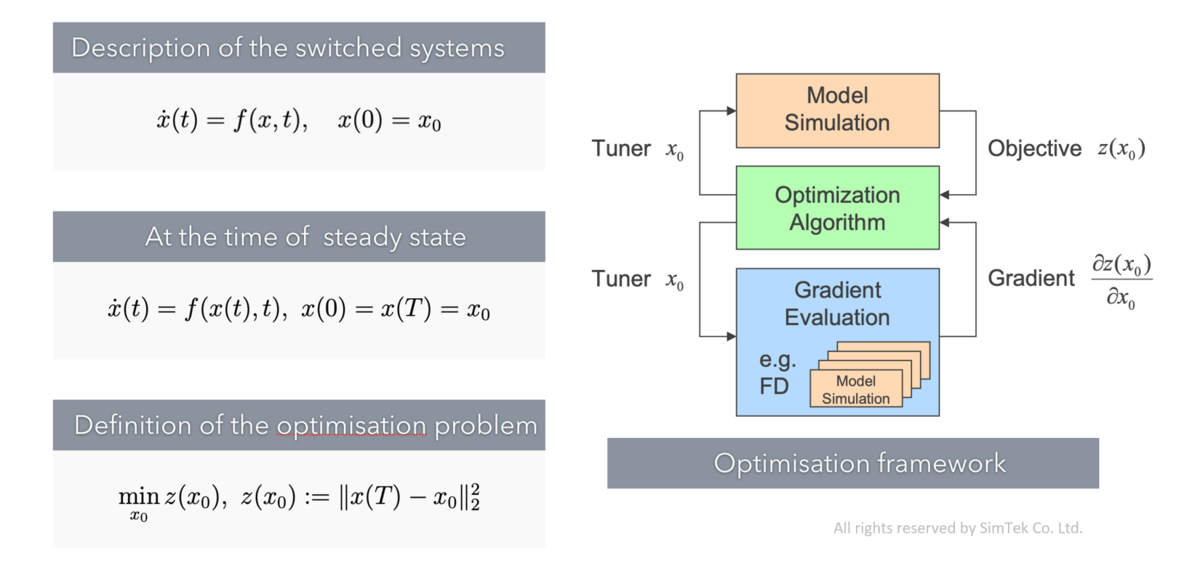

Model-based Optimization

System optimization is typical application by using advanced modeling and simulation technology. Optimization tasks include the optimization of the core parameters in the control algorithm, system model architecture and the parameters of the core components. By means of high precise models and optimization tools, the iterative optimization for software can be realized. It can significantly increase the efficiency of product development and design. In the past projects with leading industrial companies such as Airbus, BMW, Daimler and so on, model based optimization was always a essential topic. As shown in the figure, it is an optimization-based framework for fast steady-state calculation, built by SimTek team members within Airbus power quality analysis project.

Software Development

Development of system engineering related tool and software

- Design of complex control system

- Design and development of rapid control prototype

- Development of control algorithms based on inverse model

- Development of model-based predictive control (MPC) algorithms

SIMTEK provides customized software interface and development services of simulation platform to meet special application requirements, and helps customers zo quickly achieve their desired goals.

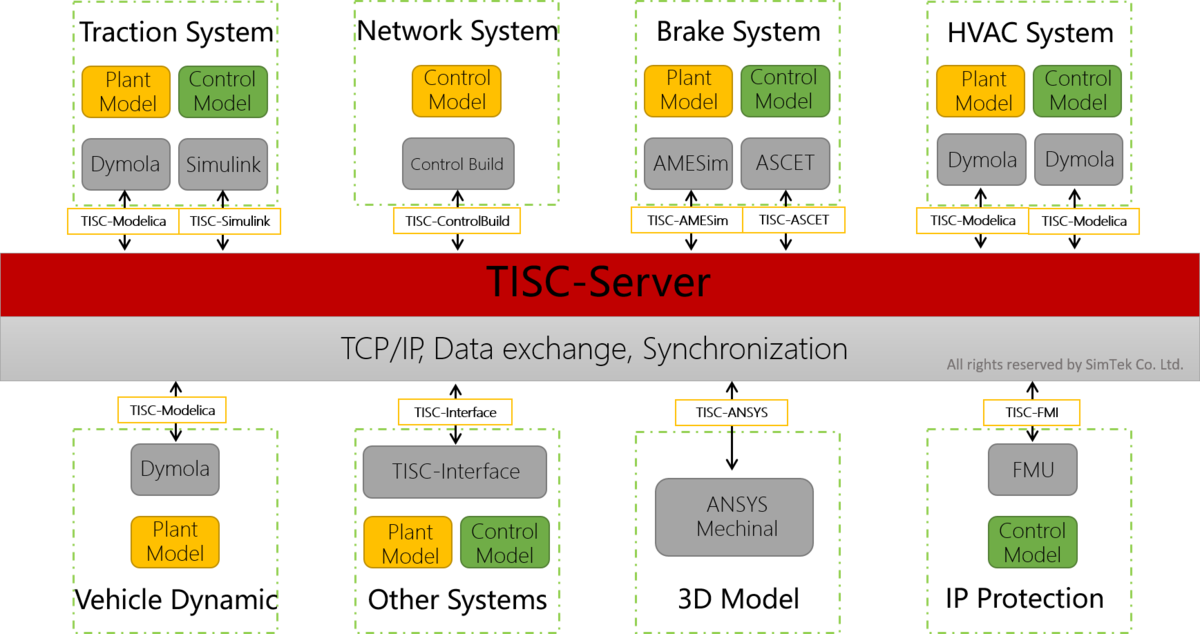

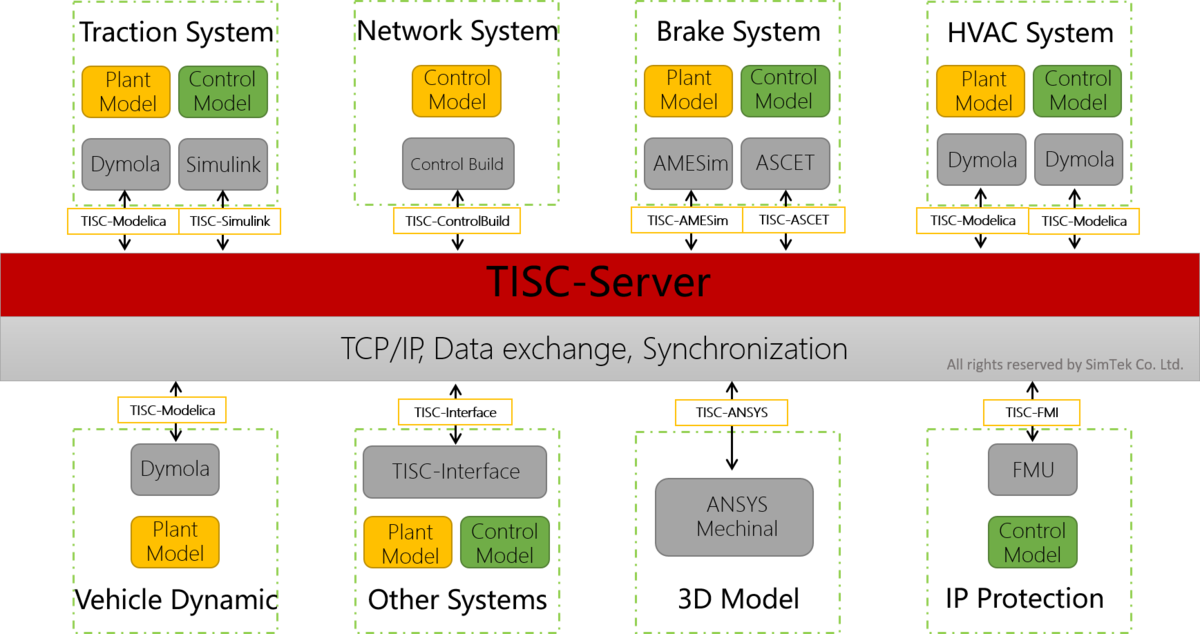

- Development of TISC interface for distributed co-simulation

- Development of FMI interface

- FMU-based heterogeneous model integrated simulation platform

- Distributed co-simulation test platform

- Virtual test platform for fuel cells

- Virtual test platform for automotive thermal management system

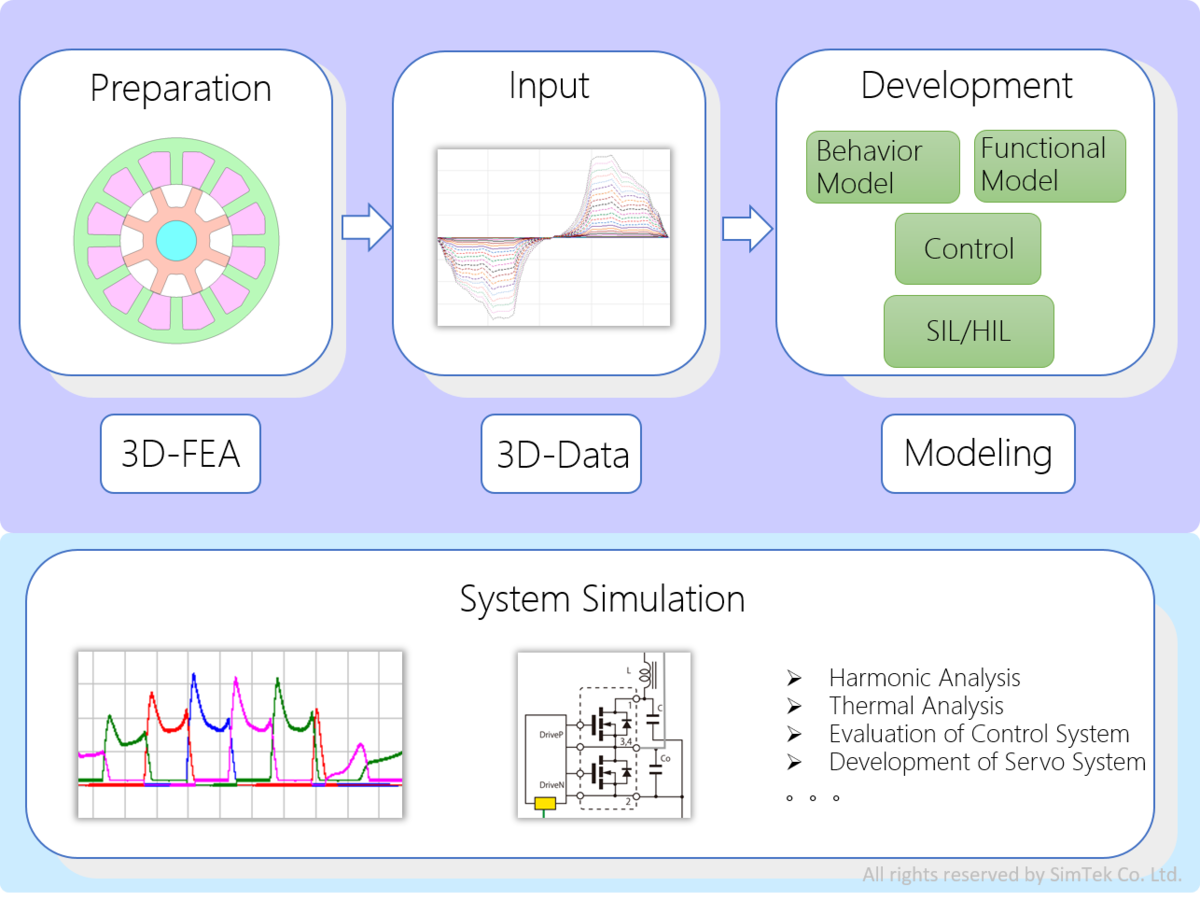

Design and Development of Servo Motor

Based on Modelica language and FEM computing tools, SimTek combines 1D-3D coupling simulation technology to achieve better motor design and control development. Optimization for specific performance indicators to satisfy different customer expectations can be done. SIMTEK cooperates with German motor design company to provide complete solutions for Chinese high-end servo motor market, covering specification, design and manufacture. For a brand-new motor design project, the design cycle is usually around 6-9 months. Besids, the performance of designed motor can match the most advanced motor in Europe and the United States. Motor structure and system design services include

- Permanent magnet synchronous motor

- Switched reluctance motor

- Brushless DC motor

- Multiphase AC motor

- Controller development

Training

Modelica Introduction Course

Operation Method and Modeling Process of Dymola Software

Simulation flow and post-processing in Dymola software

Introduction to Modelica Grammar

Modelica Modeling Example

Modelica Advanced Course

Introduction of MSL

Modelica Commerical Library and Application

System Model Development Process and Management

System Model Debugging and Processing

New Energy Vehicles Course

Design of Power Battery System

Design of Fuel Cell System

Design of Motor and Control System

Design of Thermal Management System

Simulation Tools Advanced Course

Introduction of FMI and Application

Co-simulation example based on Dymola and other software

TISC Co-simulation Case

Application of SIMTEK Cloud Computing Tool

System Iterative Optimization Course

Introduction of Design Library

Design an x d Optimization of Control System based on Iterative Optimization

Applying Iterative Optimization to System Model Parameters Joint Use of FMU and External Optimization Tools

More Electric Aircraft Course

Modeling Method of Aircraft Electrical System

Power Supply Stability Analysis Based on Model

Demand Modeling for Dynamic Design of Electrical System

System Stability and Power Quality Design Platform Based on Iterative Optimization